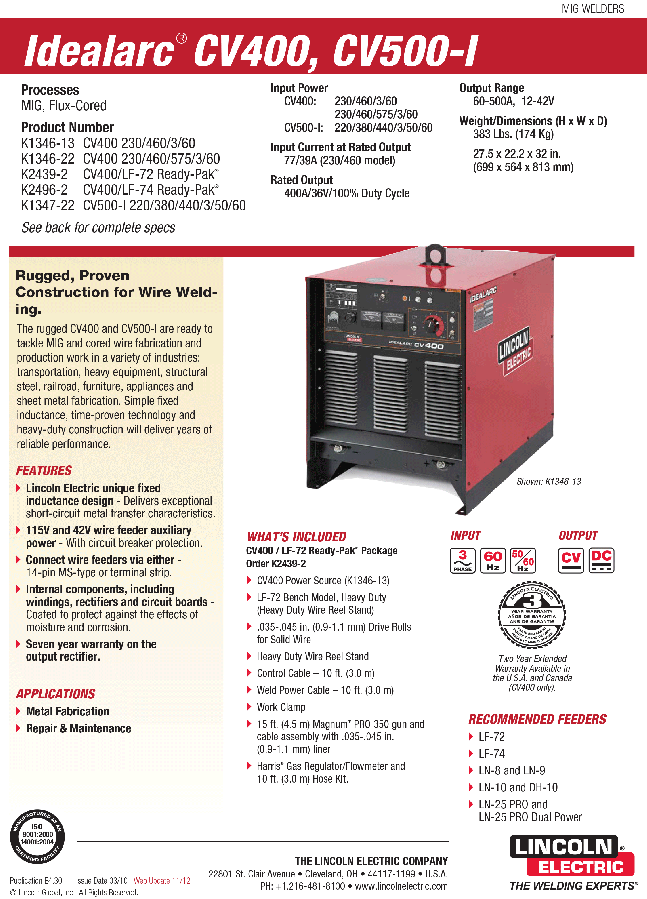

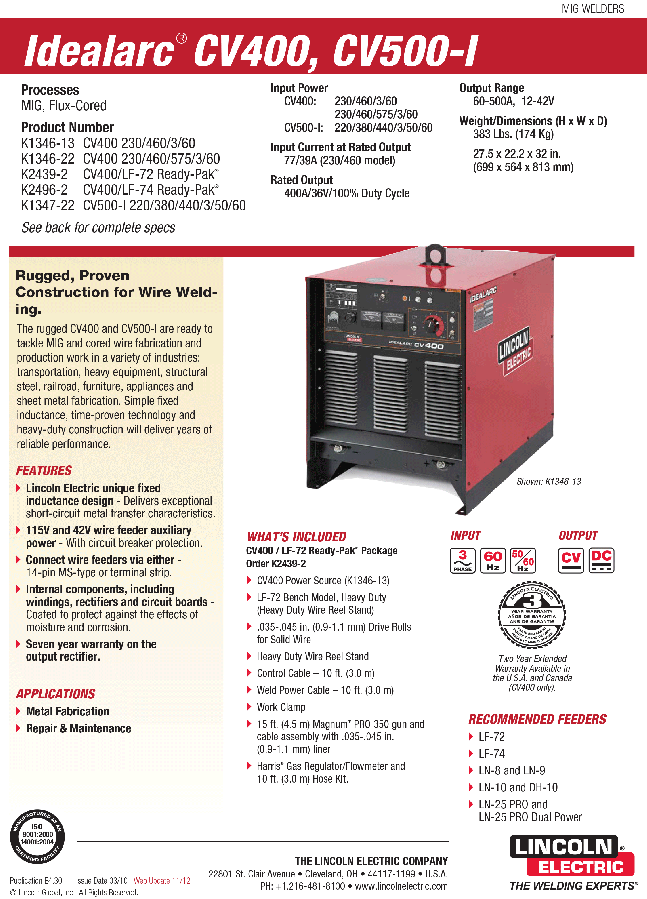

The rugged CV-400 is ready to tackle MIG and cored wire fabrication and production work in a variety of industries: transportation, heavy equipment, structural steel, railroad, furniture, appliances and sheet metal fabrication. Simple fixed inductance, time-proven technology and heavy-duty construction will deliver years of reliable performance.Advantage Lincoln Lincoln's unique fixed inductance design delivers exceptional short-circuit metal transfer characteristics.

Features

- Wire feeders can be connected via either 14-pin MS-type or terminal strip

- Auxiliary power options: 115V and 42V with circuit breaker protection

- Internal components coated for protection against moisture and corrosion

- Electronic and thermostatic protection against current overload and excessive temperatures

- Indicator light signals when machine is reset

- Warranty: Three years on parts and labor, seven years on the power rectifier

- Includes:

- CV-400 (K1346-13) welding machine

- LF-74 Bench Model Heavy Duty (K2426-2) wire feeder

- Magnum 400 MIG Gun with 15 ft cable

- Weld Power Cable - 10 ft

- Work Cable - 10 ft

- Work Clamp (K910-2)

- Harris Flowmeter Regulator and Gas Hose (3100211)

- Package does not include input power cord

- Shielding gas to be purchased separately

- Shipped fully assembled

Specifications

What's Included

What's Included

-

CV400 Power Source (K1346-13)

-

LF-72 Bench Model, Heavy Duty

-

.035-.045 in. (0.9-1.1 mm) Drive Rolls for Solid Wire

-

Heavy Duty Wire Reel Stand

-

Control Cable – 10 ft. (3.0 m)

-

Weld Power Cable – 10 ft. (3.0 m)

-

Work Clamp

-

15 ft. (4.5 m) Magnum PRO 350 gun and cable assembly with .035-.045 in. (0.9-1.1 mm) liner

-

Harris Gas Regulator/Flowmeter and 10 ft. (3.0 m) Hose Kit.

FAQs

The VRTEX® Mobile simulates the GMAW (short arc, spray, pulse and STT® metal transfers) and FCAW (Self-shielded and Gas-shielded) processes in the standard system. SMAW (E6010, E6013, and E7018) is an optional hardware and software kit.

SMAW (Optional on VRTEX® Mobile)

- E6010 (Fleetweld®® 5P+)

- E7018 (Excalibur® 7018)

- E6013 (Fleetweld® 37)

GMAW

- Short Arc (.035” SuperArc® L-56)

- Axial Spray (.045” SuperArc® L-56)

- Pulse (.045” SuperArc® L-56)

- STT® Surface Tension Transfer® (.045” SuperArc® L-56)

FCAW

- Gas-shielded .045 “ (UltraCore® 71A85)

- Self-Shielded 5/64” (Innershield® NR-232)

The VRTEX® Mobile comes with 3 welding coupons (Flat Plate, Tee Joint, Groove Joint) that can be used in limited positions.

- Plate: Flat, Horizontal, Vertical and Overhead

- Pipe: 2G, 5G and 6G

- The VRTEX® Mobile supports limited positions:

- Plate: Flat, Horizontal and Vertical

- Push and drag GMAW techniques

- Stringer beads

- Weave techniques – straight, triangle and box weave

Recently released! The VRTEX® has now expanded language support for Portuguese (Brazilian) and Russian.

Input current: 4A @ 115, 2A @ 230

- The VRTEX® system requires a space of 8’ L x 8’ D x 8’ H (2.4 m x 2.4 m x 2.4 m).

- When operating multiple units in one location, alternate between standard and alternate frequency systems (unique part numbers are identified).

- The VRTEX® system is not designed for operation in harsh environments. Recommendations are listed in the instruction manual.

- Avoid magnetic fields, conductive and high frequency objects and processes.

- An uninterruptible power supply (UPS) may be required for protection of the system from power irregularities and/or disruptions

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Recently viewed